For centuries, bamboo has been romanticized in art and poetry as a symbol of resilience and elegance. In its natural form, it’s the quintessential material of traditional Asian architecture, simple bamboo furniture, and culinary bamboo steamers. But to see bamboo only in this light is to see an acorn and miss the mighty oak. We are standing at the forefront of a quiet revolution, where advanced science and innovative engineering are transforming this humble grass into an important material of the future. This transformation is known as bamboo deep processing, and it’s poised to change how we build, what we wear, and even how we approach sustainability.

This journey from a hollow stalk to a high-tech marvel is not a single step but a sophisticated cascade of processes that fundamentally deconstruct and reassemble bamboo at a molecular level.

The First Cut: Understanding the Raw Material

Before diving into the processes, it’s important to understand what makes bamboo so special. Bamboo is not a tree; it’s a giant, fast-growing grass. This botanical distinction is the root of its superpowers:

- Unmatched Growth Rate: Some species can grow up to 90 cm in a single day, reaching maturity just in 3-5 years, compared to decades for hardwood trees.

- Superior Tensile Strength: Bamboo’s fibers run axially, giving it a tensile strength that can rival steel.

- Natural Hardness: Its silica content gives it a Janka hardness rating that surpasses many hardwoods like oak and maple.

- Inherent Sustainability: It requires no pesticides, little water, and self-regenerates from its root system, preventing soil erosion.

However, raw bamboo has its disadvantages: it’s susceptible to insect attack, can crack and split as it dries, and its cylindrical, nodal form limits its structural applications. Deep processing is the key to overcoming these limitations and amplifying its innate strengths.

The Alchemy of Bamboo Deep Processing: Core Technologies

Deep processing can be broadly categorized into two paths: one that reconfigures its form and another that breaks it down to its very building blocks.

Path 1: Re-engineering the Form – Bamboo-Based Composites

This path involves breaking bamboo down into smaller elements and then reassembling them into stable, uniform, and scalable sheets or blocks.

- Bamboo Strip Lamination:

This is the first step beyond solid bamboo canes.The culm is split into strips, which are then planed flat. These strips are:

- Dried to reduce moisture content and prevent future warping.

- Treated to remove starches and sugars that attract insects.

- Laminated using high-pressure presses and waterproof, formaldehyde-free adhesives.

The resulting products are incredibly durable and visually stunning:

- Bamboo Lumber & Planks: Used for bamboo flooring, decking, and tabletops, offering a modern aesthetic with the durability of hardwood.

- Curved Bamboo Furniture: The laminated strips can be bent and molded under heat and pressure to create ergonomic and elegant bamboo furniture designs impossible with solid wood.

- Bamboo Plywood and Mat Board:

Here,the bamboo is further dissected. The strips are woven into mats or cross-laminated in layers. This cross-graining technique, borrowed from traditional plywood manufacturing, neutralizes the wood’s tendency to expand and contract, resulting in a dimensionally stable panel. These panels are used for bamboo products, such as bamboo chair, bamboo table, bamboo photo frame, bamboo waste bin, bamboo tray, wall cladding, and even as concrete formwork that can be reused dozens of times.

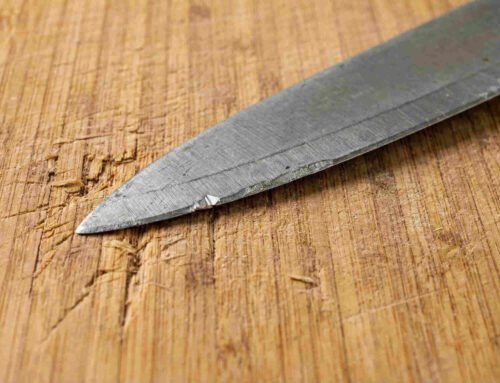

- The Pinnacle of Re-engineering: Strand Woven Bamboo

This is perhaps the most impressive form of bamboo composite.The process is intense:

- Crushing: Bamboo culms are passed through a crusher, separating them into a mass of coarse fibers or “strands.”

- Impregnation: These strands are soaked in a resin binder.

- Pressing and Coking: The resin-soaked strands are placed in a mold and subjected to extreme heat and pressure. This process, similar to forging metal, fuses the strands into a super-dense, homogenous block.

The result is a material that is:

- Harder than Maple: With a Janka hardness rating often exceeding 3000 lbs, it’s a top choice for high-traffic commercial flooring and bamboo cutting boards.

- Extremely Durable: Resistant to dents, scratches, and moisture.

- Versatile: Can be milled, routed, and worked like the toughest hardwoods.

Path 2: Deconstructing to the Fiber – The World of Bamboo-Based Biomass

This path is more chemical than mechanical, breaking bamboo down to its cellulose fibers and beyond, opening up a universe of applications.

- Bamboo Fiber and Textiles:

This is one of the most well-known yet often misunderstood deep-processing methods. There are two primary methods:

- Mechanical Processing (Bamboo Linen): Similar to flax or hemp, the bamboo is crushed and natural enzymes are used to break down the pectin, allowing the fibers to be combed out and spun into yarn. This method is eco-friendly but labor-intensive and expensive, resulting in a coarse, linen-like fabric.

- Chemical Processing (Viscose/Rayon): This is the dominant method. Bamboo pulp is dissolved in a chemical solvent (like sodium hydroxide and carbon disulfide) to create a viscous solution. This solution is then forced through a spinneret into a chemical bath, where it solidifies into fine filaments. These filaments are spun into yarn.

The result is the soft, silky “bamboo fabric” found in sheets, t-shirts, and towels. It’s breathable, moisture-wicking, and thermally regulating. It’s very important, however, to acknowledge that while the feedstock (bamboo) is sustainable, the chemical process itself has environmental impacts if not managed in a closed-loop system. Leading manufacturers are now adopting Lyocell-type processes (using non-toxic solvents) to produce what is often branded as “bamboo lyocell,” which is far more environmentally friendly.

- Bamboo Pulp and Paper:

Bamboo’s long fibers make for excellent paper pulp. It grows much faster than trees, offering a more rapid renewable source for paper products. While it has been used for centuries in Asia, modern deep processing is making bamboo pulp competitive for high-quality printing paper, tissue, and packaging, reducing the pressure on ancient and old-growth forests.

- Bamboo Charcoal and Activated Carbon:

This process involves pyrolysis– heating bamboo in a low-oxygen environment. The resulting bamboo charcoal is an ideal powerhouse material:

- Purification: With a vast surface area, it’s processed into activated carbon used in water filters, air purifiers, and even in medical settings to treat poisonings.

- Odor Absorption: Used in sachets for shoes, refrigerators, and closets.

- Soil Amendment: Bamboo biochar improves soil fertility and sequesters carbon.

- Textiles: Bamboo charcoal can be embedded into fibers to create odor-resistant and far-infrared emitting clothing.

- The Frontier: Bamboo-Based Bioplastics and Bio-composites

This is where deep processing gets truly futuristic. By extracting cellulose or nanocellulose from bamboo, scientists are creating:

- Bamboo Bioplastics: These can be used for everything from disposable cutlery and packaging to electronic casings. They are biodegradable and derived from a renewable source, offering an alternative to petroleum-based plastics.

- Nanocellulose: When broken down to the nano-scale, bamboo fibers form a material with incredible strength and lightness. It has potential in reinforcing composites for the automotive and aerospace industries, creating transparent films for electronics, and even in biomedical applications like wound dressings and drug delivery systems.

The Green Heart of the Matter: Sustainability and Economic Impact

The promise of deep-processed bamboo isn’t just technological; it’s profoundly ecological and social.

- Carbon Sequestration Champion: A bamboo forest sequesters carbon at a rate significantly higher than many trees. When turned into durable products like bamboo flooring or bamboo furniture, that carbon is locked away for decades. This creates a powerful carbon sink, making it a crucial tool in the fight against climate change.

- A Circular Economy Model: Bamboo thrives on marginal land unsuitable for agriculture. Its root system prevents erosion and its fallen leaves enrich the soil. Almost every part of the plant can be used, and waste from one process (e.g., sawdust from strip production) can become feedstock for another (e.g., charcoal briquettes). This creates an almost-zero-waste cycle.

- Rural Revitalization: Bamboo cultivation and its subsequent deep processing create a value chain which generates rural employment—from farming and harvesting to working in processing facilities. This supplies a sustainable livelihood, curbs urban migration, and empowers communities, especially in developing countries.

Challenges and The Path Forward

Despite its big potential, the industry also faces hurdles that must be addressed for it to mature fully.

- Standardization and Certification: Ensuring consistent quality and certifying the sustainability of both the raw material and the manufacturing processes (especially for textiles) is critical for consumer trust. Organizations like the Forest Stewardship Council (FSC) are now certifying bamboo.

- Technological Investment: Deep processing requests sophisticated, also expensive machinery. Making this technology accessible to small and medium-sized companies in bamboo-growing regions is a key challenge.

- Consumer Education: Dispelling myths (e.g., the purely “natural” process of bamboo viscose) and educating consumers about the different types of bamboo products and their true environmental footprint is necessary.

Conclusion: Not Just a Substitute, But a Superior Choice

We have moved far beyond the image of a simple bamboo stalk. Through the magic of bamboo deep processing, bamboo is being reborn. It is no longer just a “green alternative” or a “substitute” for wood or plastic. In many applications—from strand-woven bamboo flooring that outlasts oak, to breathable fabrics that feel like silk, to advanced bioplastics—it is a superior material in its own right.

It represents a powerful convergence of ancient wisdom and frontier innovation, offering a blueprint for a more sustainable and materially abundant future. The next time you see a bamboo grove, don’t just see the plant. See the potential for the bamboo floor you walk on, the clothes you wear, the car you drive, and the future we can build—all from one of nature’s most rapid and resilient gifts. The bamboo deep processing is not just an industry; it’s a paradigm shift, proving that true sustainability doesn’t mean going without, but rather learning to work in harmony with nature’s genius.

Leave A Comment