To provent bamboo getting mouldy a complete system must be established

Preventing mold growth on bamboo canes is a complex and systematic project for bamboo product exporters, need strict control over multiple stages, including raw material handling, processing, warehousing management, and transportation packaging. Following is a comprehensive prevention plan summarized by our company on the basis of practical experience:

-

Controlling the Conditions for Mold Growth is the Most Crucial Factor

As we all know, mold growth requires four key elements: nutrients (the organic matter in the bamboo itself), suitable temperature (20-35°C), humidity (high humidity > 75% RH), and oxygen. All our measures revolve around eliminating these conditions.

-

Prevention and Control Measures at Different Stages

1.Raw Material and Processing Stage

1.1.Bamboo Selection: Process bamboo promptly after harvesting, avoiding the use of bamboo with existing mold spots, insect holes, or excessive moisture content. It is better to harvest in winter when the starch content is lower, making it less prone to mold.

1.2.Thorough Drying: It is the most critical and fundamental step.

1.3.Natural Drying: Put the bamboo canes under a well-ventilated, sun-protected, and rain-proof rack, stacking them neatly to allow natural air circulation to reduce moisture. The disadvantages are that it is time-consuming and highly sensitive to weather conditions.

1.4.Manual Drying: Using kiln drying or specialized drying equipment, the moisture content of the bamboo canes is forcibly reduced to below 12% (export standards typically require 8-12%). This is the most reliable and efficient method.

1.5.Testing: It is essential to use a wood moisture meter for multi-point testing to ensure that the moisture content of the entire batch of bamboo canes is similarly within the standard range.

2.Anti-Mold Treatment Stage for Bamboo Canes

After achieving the requested drying level, anti-mold treatment is carried out to establish a “chemical barrier.”

2.1.Immersion Method: Immerse the bamboo canes in an anti-mold agent solution for a thorough soaking (usually 24-48 hours), then remove and air dry. This method has deep penetration and long-lasting effects.

2.2.Brushing/Spraying Method: Apply a coating or high-pressure spray to the dried bamboo cane surface, ensuring complete coverage.

2.3.Vacuum Pressurization Method: An industrial-grade treatment, the bamboo canes are placed in a pressure tank, a vacuum is created, and then the anti-mold agent is injected. Under pressure, the solution deeply penetrates the bamboo canes. This method has the best effect, but the disadvantage is that it is also the most expensive.

Commonly Used Mold Inhibitors:

– Eco-friendly Boric Acid/Borate Series: Such as boric acid, borax, sodium octaborate, etc. Good mold and insect resistance, low cost, and relatively eco-friendly, which is the common choice for exporting to European and American markets.

– Quaternary Ammonium Copper (ACQ), etc.: Strong anti-corrosion and anti-mold properties, but may contain copper; environmental regulations must be considered.

– New Eco-friendly Mold Inhibitors: Such as propiconazole, tebuconazole, etc., low-toxicity, high-efficiency professional wood mold inhibitors.

– Special Note: The selected mold inhibitor must comply with the environmental and safety regulations of the destination country (such as the EU’s REACH, Biocidal Products Regulation, and the US EPA standards).

3.Warehouse Management Stage After Bamboo Cane Arrives

3.1.Environmental Control: The warehouse must be ventilated, dry, and cool. Install temperature and humidity meters for real-time monitoring; ideally, humidity should be controlled below 60% RH. Use dehumidifiers if necessary.

3.2.Stacking Method: Use a crisscross pattern or pallets to elevate the bamboo canes, ensuring airflow both vertically and horizontally, and avoiding contact with the ground or walls.

3.3.Regular Inspection: Regularly check the core and bottom bamboo canes for signs of mold to prevent problems before they occur.

4.Bamboo Cane Packaging and Transportation Stages

4.1.Sealed Moisture-Proof Packaging: This is the last line of defense against moisture during transportation.

4.2.Internal: Wrap each bamboo cane or bundle of bamboo canes with anti-mold paper or moisture-proof film (such as vapor phase rust inhibitor film).

4.3.External: Wrap the entire bamboo cane with high-strength waterproof PE woven bags or shrink film. Moisture-proof felt or a drying shed should be laid inside the container.

4.4.Desiccant: Place sufficient strong desiccant (such as silica gel desiccant) inside the packaging and inside the container, and calculate the dosage and moisture absorption period.

4.5.Container Inspection: Before loading, it is necessary to check that the container is intact (no holes or rust on the top, sides, or bottom), clean, dry, and free of mold. A desiccant container is required.

4.6.Anti-condensation treatment: For shipments to ports with large temperature differences and high humidity (such as from northern China to tropical regions), “container rain” may occur on the inner walls of the container. Container desiccant bars (moisture-absorbing bars) can be hung inside the container, or anti-condensation coatings can be used.

-

Suggested Standard Operating Procedures

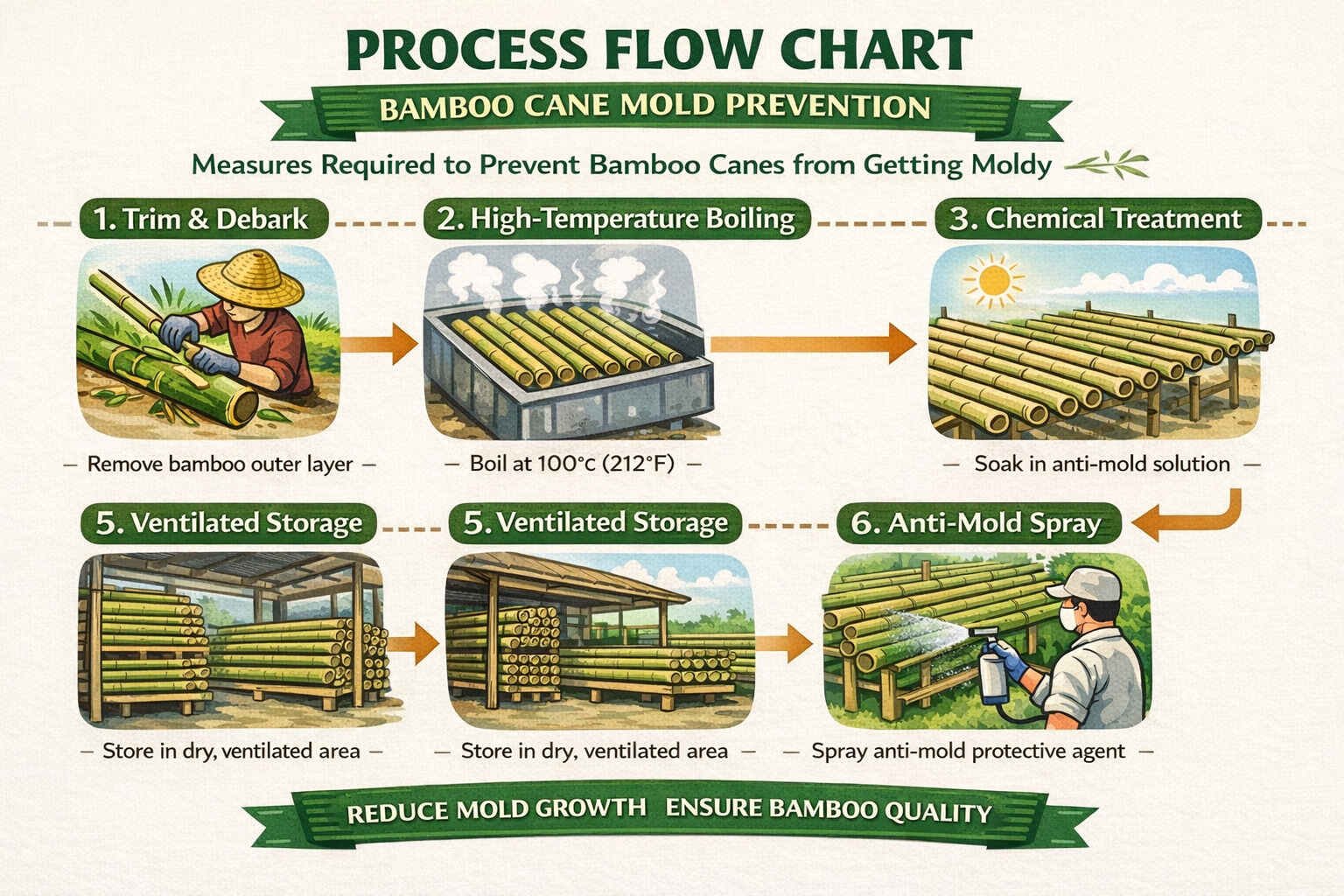

1.Felling and Initial Selection → 2. Timely Bamboo Splitting/Processing → 3. Artificial Drying (to moisture content ≤12%) → 4. Anti-mold Treatment (Soaking/Spraying) → 5. Secondary Drying (Evaporation of Surface Solution) → 6. Quality Inspection (Moisture Content, Anti-mold Effect) → 7. Moisture-proof Packaging (Anti-mold Paper + Desiccant + Waterproof Outer Packaging) → 8. Temporary Storage in a Qualified Warehouse → 9. Container Inspection Before Loading → 10. Scientific Loading (Elevation, Ventilation, Hanging Drying Rods) → 11. Documentation (Record the moisture content, anti-mold treatment parameters, and packaging details for each batch)

-

Special Considerations

Regulatory Compliance: As plant products, bamboo products typically require a phytosanitary certificate. It is essential to ensure that the product is free of live mold and pests and meets the quarantine requirements of the importing country.

Customer Communication: Inform customers about your anti-mold technology and standards as a selling point to increase their confidence. Relevant treatment certificates or test reports can be provided.

In summary, preventing mold growth on exported bamboo canes cannot be solved by a single measure. A complete system must be established, with “thorough drying” as the core, “anti-mold treatment” as a reinforcement, “moisture-proof packaging” as a guarantee, and “comprehensive environmental control” as support. Strictly implementing these steps will ensure that your bamboo canes are delivered to overseas clients in very good condition to the greatest extent possible.

Leave A Comment