Choose a bamboo toothbrush, embrace a sustainable lifestyle

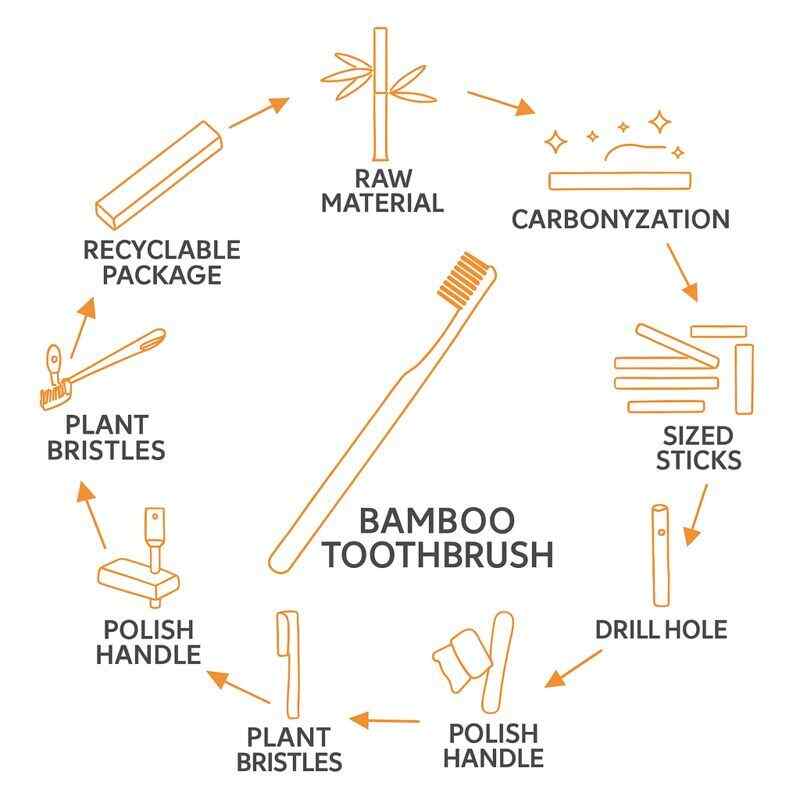

In today’s society, plastic pollution is more and more serious. Choosing a bamboo toothbrush means choosing an eco-friendly lifestyle, and bamboo toothbrushes are gradually integrating into people’s daily lives. A small bamboo toothbrush, maybe simple, but represents the meticulous process of combining traditional wisdom with modern craftsmanship. From the initial selection of bamboo materials to the finished product packaging, every step reflects respect and understanding for natural materials, a true embodiment of harmonious coexistence between humans and nature.

-

Raw Material Selection

The production of bamboo toothbrushes begins with the selection of high-quality moso bamboo. Not all bamboo is suitable for toothbrush making. Manufacturers usually choose moso bamboo that has grown for more than three years with a diameter of 5-8 centimeters. Bamboo of this age has a moderate fiber density, possessing both sufficient hardness and good toughness. The bamboo selection time is also important; usually, manufacturers choose it before the beginning of spring. During this period, the bamboo has lower internal moisture and sugar content, making it less susceptible to insects and mold. People judge the internal condition of the bamboo by tapping it and listening to the sound. If the bamboo produces a deep, resonant sound, it indicates that the quality meets the requirements. Besides, the selected bamboo needs to have a relatively long internode spacing, have same wall thickness, and be free of any cracks or insect damage. This is fundamental to ensure the quality of the subsequent processing steps.

-

Cutting the Bamboo

After being felled, the bamboo cannot be used immediately; it needs to be cut first. Workers saw the bamboo into equal-length tubes based on the approximate length of a toothbrush handle (usually 16-18 cm). The next crucial step is “splitting the bamboo”—splitting it into appropriately wide strips along the natural grain of the bamboo tube. This step is very important; the cuts must follow the direction of the bamboo fibers to make sure straight edges on the split strips without damaging the fibers.

The initially formed bamboo strips undergo strict anti-mold and anti-insect treatment. This is usually done by high-temperature steaming, where the bamboo strips are placed in a special container and steamed for several hours. The high temperature kills insect eggs and bacteria within the bamboo and also promotes the extraction of some bamboo oil, increasing the natural luster of the bamboo. With the development of technology, modern bamboo processing increasingly employs eco-friendly carbonization. This involves placing bamboo strips in a high-temperature, low-oxygen carbonization furnace, forming a dense carbonized layer on the surface. This process permanently improves the bamboo’s anti-mold and antibacterial properties and creates varying shades of color.

-

Preliminary Shaping and Fine Polishing

The processed bamboo strips enter the shaping stage. Manufacturers first use planing tools to roughly shape the bamboo strips into the basic form of a toothbrush handle, removing excess bamboo green and yellow layers, retaining only the densest bamboo flesh. Through precise cutting and polishing, and based on design drawings, the contours of the toothbrush head and handle are determined.

Subsequently, a series of sandpapers, progressing from coarse to fine (from 180 grit to over 1000 grit), are used to repeatedly hand-polish the bamboo handle, completely eliminating burrs and giving the surface a smooth, delicate feel, as if covered with a warm patina. Polishing requires considerable patience from the workers; it’s a display of skill and a deep connection with the material—judging the smoothness of each curve through tactile examination to ensure the product perfectly conforms to the palm’s curve, to ensure provide the consumer with a perfect experience.

At the same time, the toothbrush head needs precise drilling based on the bristle implantation method (usually a metal-free implantation process). The hole diameter, depth, and density must be meticulously calculated to ensure the bristles are firmly attached without falling out, while avoiding excessive damage to the bamboo’s structure. The edges of the holes must be chamfered to prevent injury to the scalp.

-

Bristle Implantation

The selection and implantation of bristles are important steps in determining the toothbrush’s user experience. High-quality bamboo toothbrushes generally use natural pig bristles, DuPont filaments, or bamboo fiber bristles. Before implantation, the bristle tips must be rounded to effectively prevent damage to the gums.

The bristle implantation process is a highly technical step. A technique called metal-free implantation is now available, which often uses high-temperature fusion or food-grade adhesives. Workers bundle the bristles and precisely insert them into pre-drilled holes. Using a specific technique, they secure the bristles at the bottom of the holes and allow them to naturally spread out into the desired shape. The bristle density must be equal; too dense and it will be difficult to clean, too sparse and it will have effect on the cleaning effect. After completion, the bristle surface needs to be trimmed for overall flatness, and the firmness of each bristle bundle needs to be checked again.

-

Deep Processing

The semi-finished toothbrush after bristle implantation requires final deep processing. This mainly includes:

1.Fine Polishing: Polishing the bamboo handle with an ultra-high grit, even using a cloth wheel, to give it a natural luster.

2.Moisture-proof Coating: To enhance the durability of the bamboo toothbrush, it is necessary to apply a layer of natural beeswax or edible wood oil. The use of his thin film not only prevents moisture from penetrating the bamboo too quickly but also further highlights the natural texture of the bamboo. The most important thing is that it is safe and harmless.

3.Laser Engraving: Upon the requirements, brand logos or personalized patterns are laser engraved on the bamboo toothbrush handle. Laser engraving offers high precision, the protective layer on the bamboo surface can avoid being damaged like traditional engraving.

-

Final Steps: Quality Inspection and Packaging

To ensure quality and a good consumer experience, every bamboo toothbrush undergoes multiple strict quality inspections before leaving the factory. Quality inspectors carefully check the following: 1) if have minor cracks in the bamboo handle; 2) if the surface is absolutely smooth ; 3) if the bristle arrangement is neat, secure bristle placement, and if there are any unusual odors. Simulated usage tests are even conducted to ensure no problems occur within its normal lifespan.

Only products that pass quality inspection can proceed to the packaging stage. The packaging materials themselves adhere to environmental friendly principles, primarily using recycled paper or biodegradable materials. The packaging design also reflects green and eco-friendly concepts, often conveying the environmental value of bamboo toothbrushes and guiding users to use bamboo toothbrushes for sustainable consumption.

From a single moso bamboo to a usable toothbrush, the entire production process involves dozens of steps, largely depending on the experience and feel of the workers. The manufacture of bamboo toothbrushes is not only a craft, but also an expression of a lifestyle. Respecting the nature of the material, bamboo toothbrushes are no longer just simple teeth cleaning tools, but green symbol that connect consumers with nature, tradition and modernity. In daily brushing, now bamboo toothbrushes are an indispensable partner.

Leave A Comment